LanOC Reviews published Casting 3D Printed Parts

A quote from the article:

Casting 3D Printed Parts

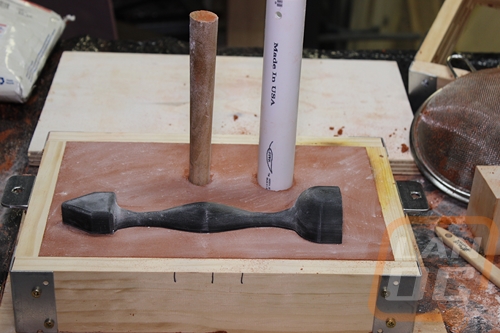

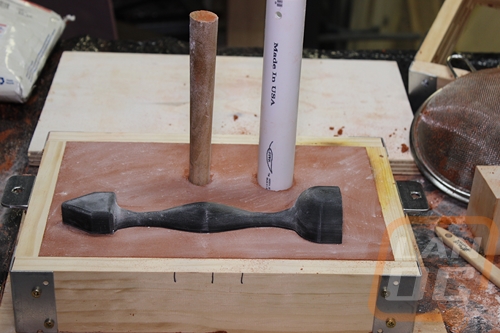

So you have had a shiny new 3D printer for a few months, your house now is full of little plastic tchotchkes. There are Little Yoda heads in the living room, some benchy boats in the bath, and an R2D2 on your desk. What’s next? You can buy fancy filaments with metal powders embedded in them so you can make your gnomes rusty or green but they’re still plastic. How does one make something metal with a 3D printer? You can spend a huge sum of money and buy a printer that can sinter metal powders together. Unless you’re NASA or SpaceX that is a lot of money. Sure, you could slap a MIG welder nozzle on your printer but that is not very precise and would take a lot of tinkering to get something useful out of it. Instead of going high tech, let’s go low tech. Casting liquid metal into sand molds is a process humans have been doing for centuries. What if you used a 3D printer to create the mold patterns for the sand in a few hours instead of the day(s) it would have taken to do by hand?

Casting 3D Printed Parts